The Early Days: Beginning Phase

HISTORY

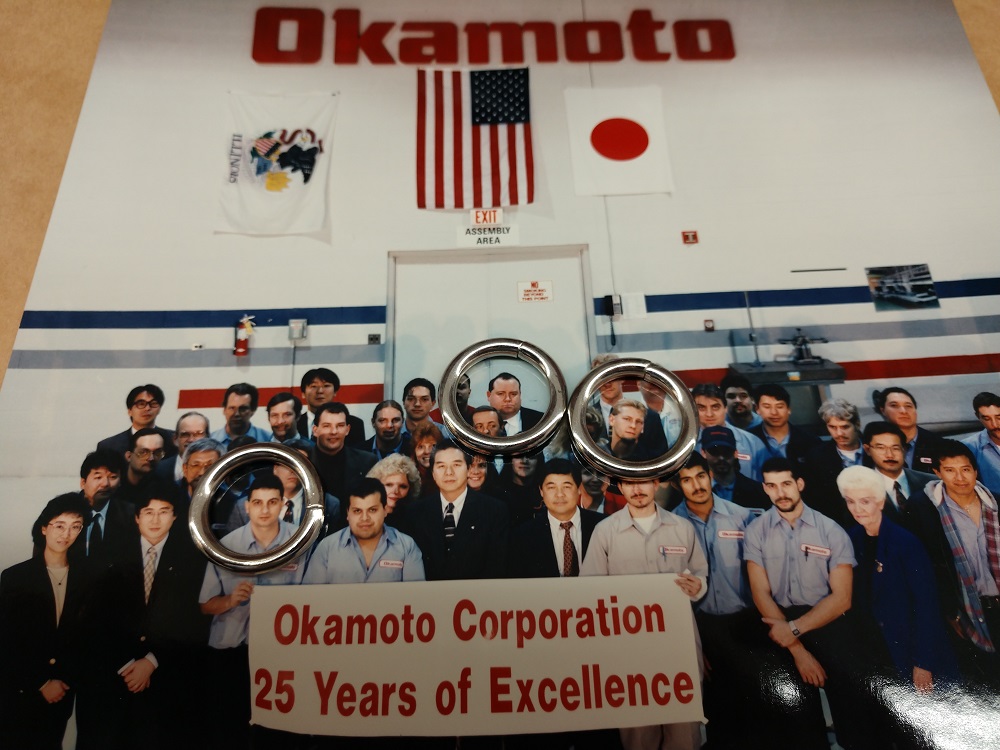

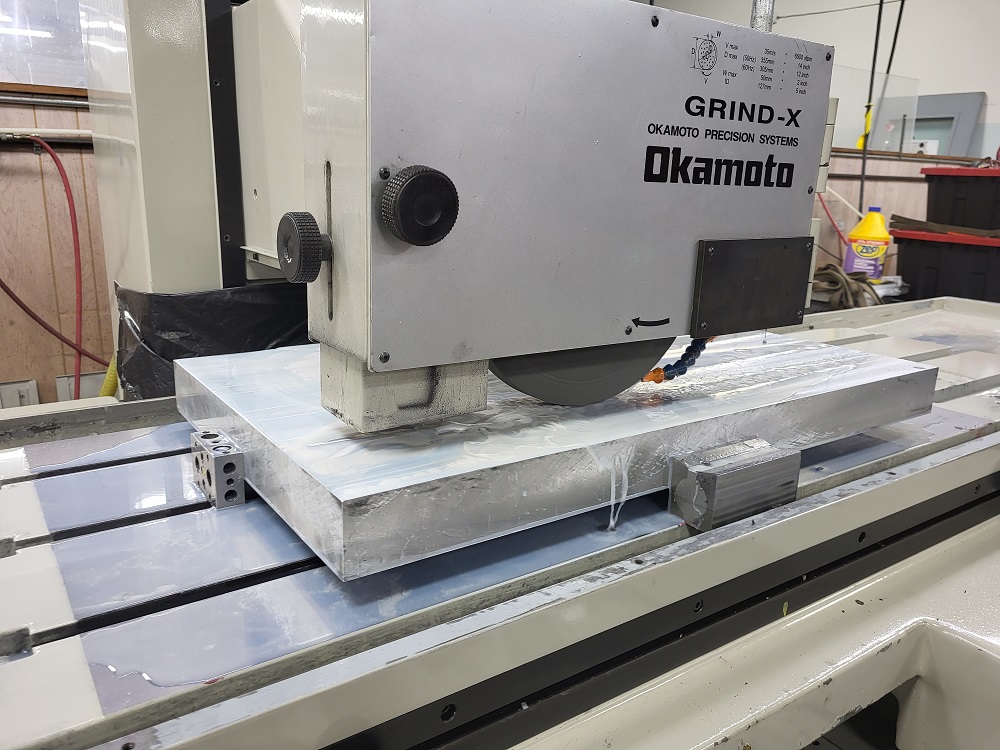

We at Waymint, Inc., began our young adult working careers by getting hired at The Okamoto Corporation, Buffalo Grove, Illinois in early 1988. Just out of High School, destiny brought both Dominick and myself, Daniel, to the Okamoto Corporation mere months apart. This was our introduction into the world of Japanese made, precision surface grinder manufacturing. The Okamoto Corporation had created an assembly line where each assembly employee was responsible for the assembly / building of their own crated surface grinder. The two differing manual grinders in need of assembly were the Linear 6/12 Manual Surface Grinder and the Linear 6/18 Manual Surface Grinder. Those in the know realize the 6/12 and the 6/18 denotes the working size of the table top / magnetic chuck size. 6/12 was a 6” x 12” work area for grinding.

Every boxed Linear arriving at the Buffalo Grove, Okamoto location was crated in a Japanese hardwood you couldn’t hammer a nail through. Each cube crate measured approximately 4’ x 4’ x 4’ and an entire Linear grinding machine was in this crate, in a thousand pieces; ready for the assembly procedure. Every sub-assembly of the build needed a focused, dedicated machinist working with his hands and mind in order for the unit to function with ease and Japanese-level precision. Every stage of the Linear build needed passing approval from our elder Japanese Assembly Line foreman / master assembler-technician. If the checking stage was failed, you continued until you were granted a passing head nod.

It was known to the employees that it would take approximately a full year to fully understand the Linear machine build without raising a question. Some got it sooner, but many took longer. Some never fully grasped the concept and simple quit.

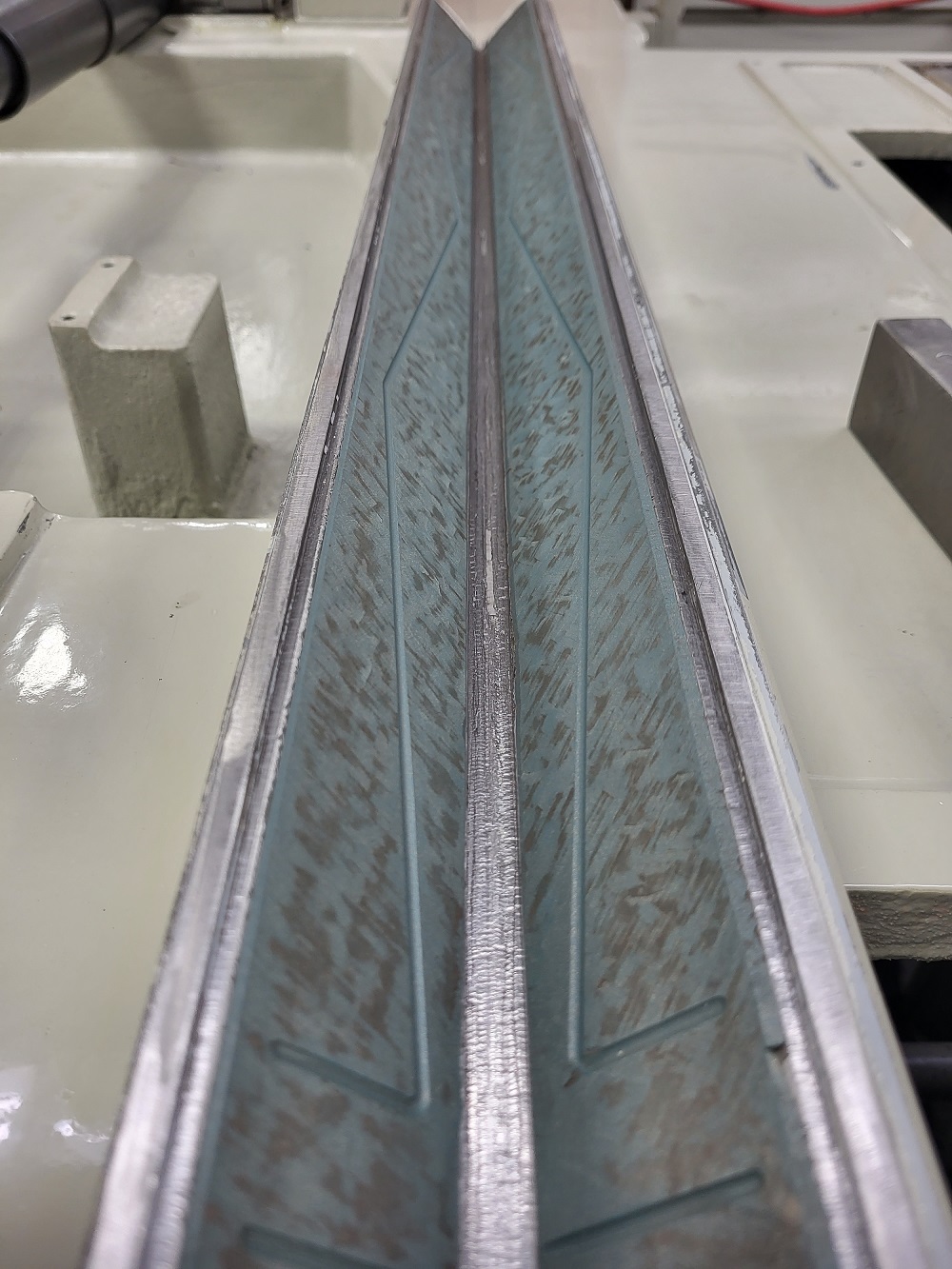

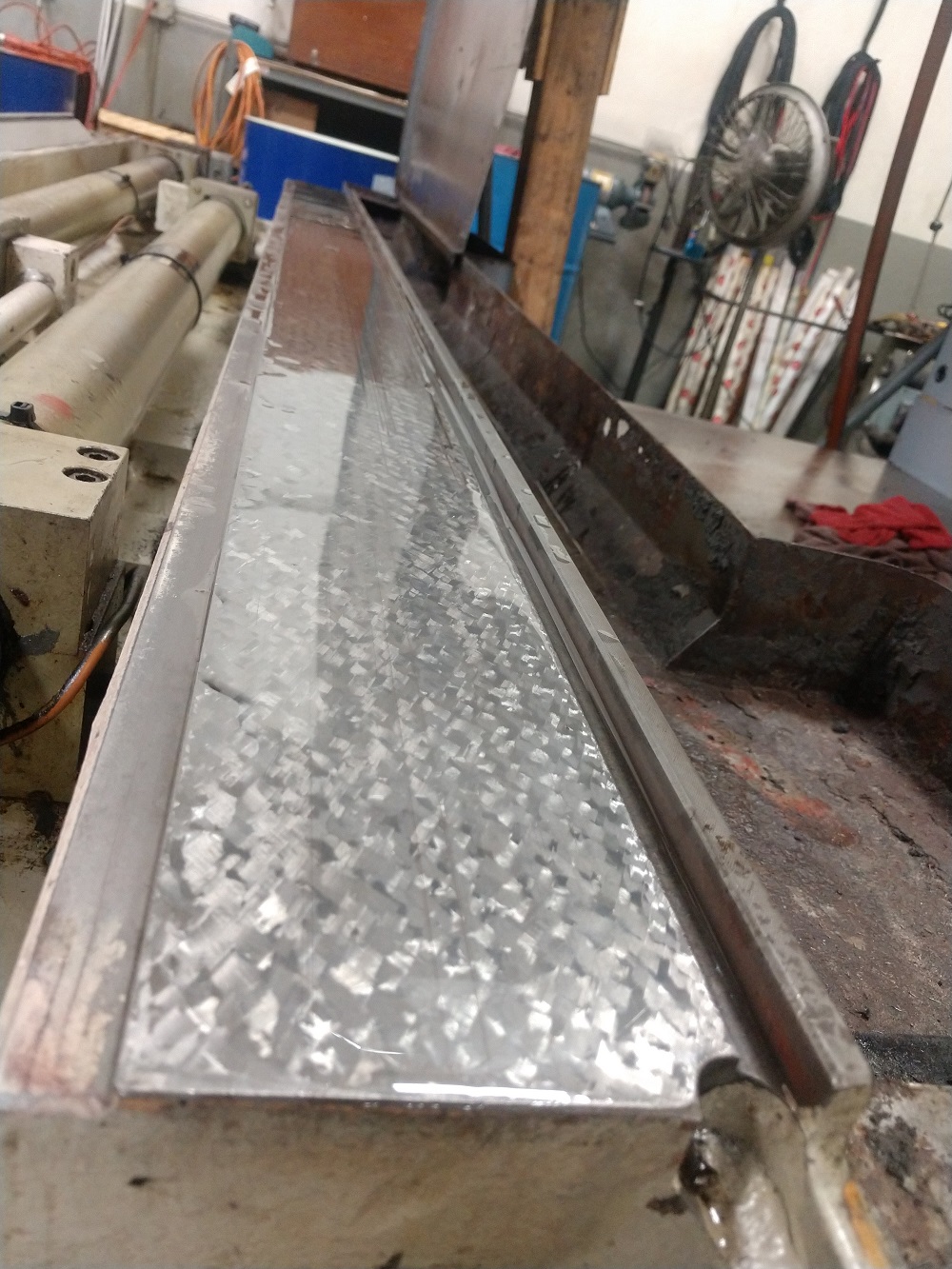

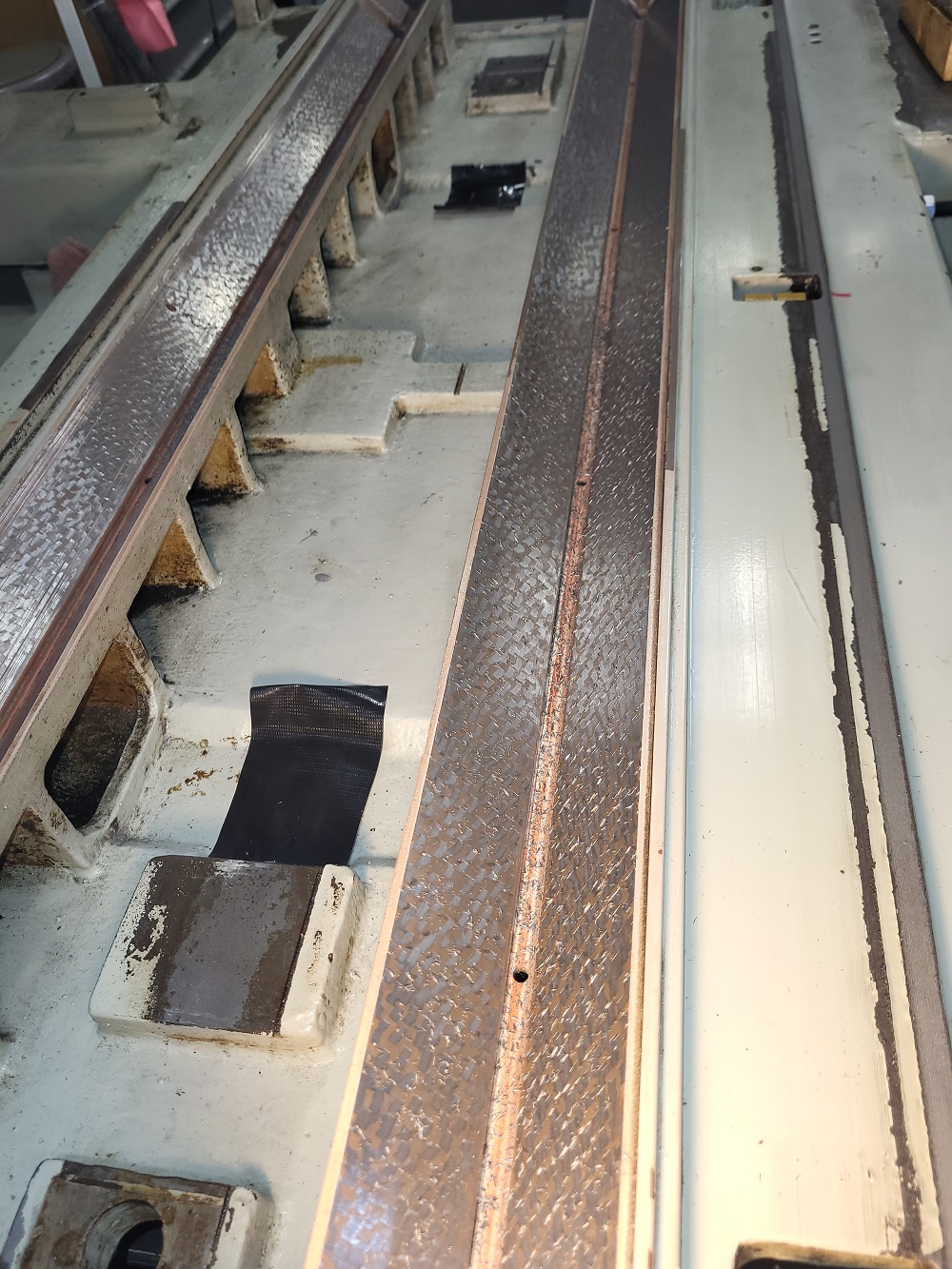

This was our introduction into hand-scraping, spindle building, proper assembly techniques, accuracy / trusted OEM tolerances, repetition and machinist integrity. The values instilled with us at these youthful ages stays with us to this very day. For every larger sized saddle and column type Okamoto grinder we restore perfectly today, our early assembly line beginnings, with our Japanese instructors with us in spirit, guide us along with every task we execute upon.

Waymint, Inc., consists of only two ex-Okamoto early day assembly technicians and are the only active OEM assembly technicians rescraping Okamoto surface grinders on-site in America! There’s no one else who can claim this incredible fact. Waymint, Inc., is superior in this regard. Waymint, Inc., is legit Okamoto OEM, period!

The Mid-Career Days: Phase 2

Our Okamoto Corporation assembly days led to Nationwide air and road-travel for new machine installation services. New machines, usually saddle-type surface grinders, 8 x 20 to 20 x 40 mid size surface grinders sat on their shipping skids wrapped in a space-age foil silver wrapping that kept moisture out of the machine’s working areas and electrical systems. Our job was to unwrap these new machines, crane-lift the machine off their shipping pallet and position the grinder upon the provided leveling pads in the customer-approved working location. Final assembly, power feeds, lubrication needs, magetic chuck grind-in and operational instructions / teaching was provided to the customer employees, sometimes multiple shifts.

This stage of our Okamoto careers came to and end with the infamous 9/11 day we as Americans will never forget. Okamoto almost immediately terminated the Linear assembly line and then began releasing employee after employee in small weekly groups behind closed doors. The chatter of “who’s next and when” was the heavy talk that had the remaining employees walking on eggshells. What we didn’t know then, that we know today, is that Okamoto had a 15-year commitment to manufacture the Linears in America before satisfying their obligations to Illinois governing officials, whereby Okamoto no longer needed to manufacture any model of their machinery in America. Everything could be brought over fully built and ready for immediate sale to customers Nationwide; hence the death of the Okamoto Assembly Line in Buffalo Grove, Illinois, which just so happened to coincide with the 9/11 tragedy. How little we knew.

Okamoto Dealer Phase: Mid-Career Continuation

Life moves pretty fast and following my personal (Daniel) exile from the Okamoto Corporation after 15.5 years, I found myself looking for new employment. Upon departing The Okamoto Corporation, I left with the fastest ever scraping and Linear assembly timeframes ever recorded in Okamoto USA history! Dominick left with the longest full time scraping appointment in Okamoto history. We’re both very proud of these accomplished facts.

Almost immediately I was employed by an industrial Spindle rebuilding company (Dynomax, Inc.) and worked my way up to the top spindle rebuilder in 5 months. At month 7, I was at the crossroads again and made a decision to join an Okamoto Dealer company that brought me back to the people I had known and a re-usage of my Okamoto assembly skill set. Rebuilding the mid-size saddle-type grinders for 7.5 additional years exercised and forged my hand-scraping skills on larger machines without the usage of the master template forms found at The Okamoto Corporation, which highly aided one in scraping to finality. Dominick again rejoined with me in employment at this unnamed location. New scraping techniques were birthed and endless hours were exhausted on hand-scraping Okamoto Surface grinders back to OEM tolerance in a non-Japanese environment. Successful, we were.

In the year 2010, we found ourselves at another fork in the road life moment. The exile had found us once again.

Current-Career Days: 2010; The Birth of Waymint, Inc.

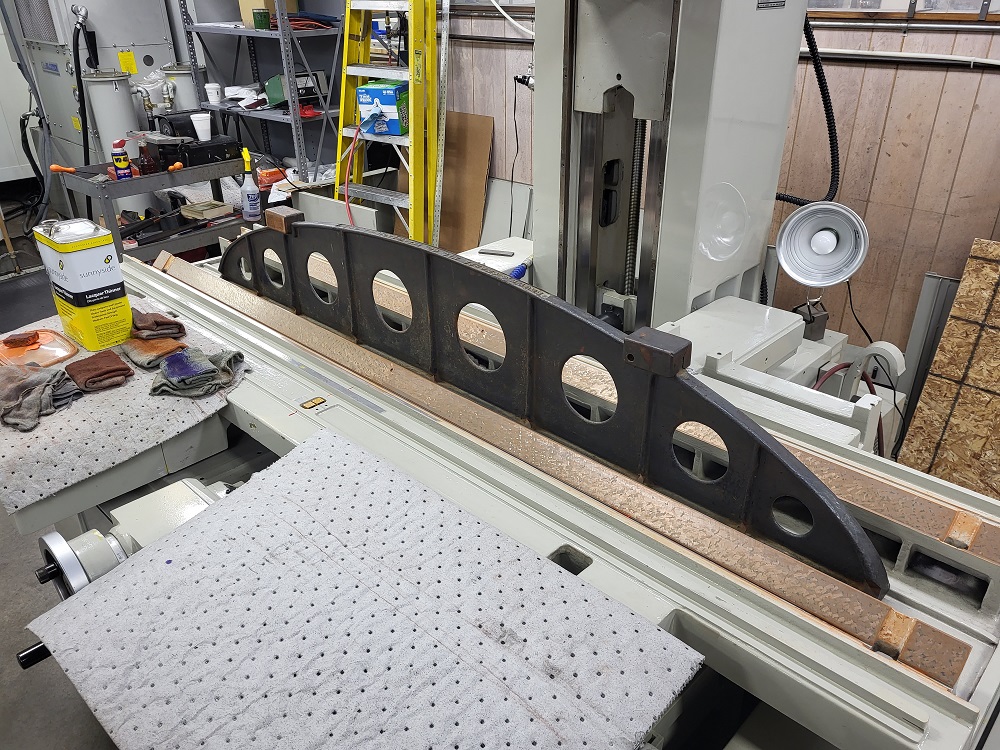

A day had come where I was tasked to scrape a highly deteriorated Okamoto 16 x 24DX on-site at a customer’s location, in front of all those machinists looking on with heavy doubt. This customer was rebuilding their own Okamoto grinder. They were doing great until the challenge of restoring the V-way accuracies was at hand. They had to call in a pro. I was tapped to answer this call. I gathered my gear and headed out to the site. A group of people surrounded the machine in utter confusion as I arrived as a 39 year old man with a small bag of tools and the knowledge they needed for the sticking point they were confronted with. With the machine largely disassembled, both the saddle and table had been put back upon the machine base in their respective locations. With everything disconnected from the saddle and table, the two heavy parts just sat there, immovable. “We can’t get these pieces to move!” They said. A group of three large men physically tried pushing the table along its V-way guideways, but to no avail. It wouldn’t budge. They brought in a forklift, butted the forks together and approached an end of the stubborn unmoving table. Just before the forks made contact, an employee raised up a two foot length of a wooden 4x4 and held it horizontally along the table’s casting end and the forklift fork tips made contact with the 4x4, acting as a cushion between the forks and machine table. The wood raising guy stepped away and we all watched what happened next. The forklift operator was given the order to begin depressing the gas pedal as the gearshift was in the forward operating position. The revving of the forklift engine gradually ramped up and yet the table remained motionless. The revving engine hit a fever pitch as I looked on at the surrounding men, many of which were smoking cigarettes and board with this particular spectacle, having seen it many times before. I looked back to the forklift with the engine nearing maximum output. The front forklift rubber wheel then suddenly spun in place, then suddenly re-gripped the floor and the forklift and table surged forward a foot of travel then stuck again. The fork truck operator then backed off having shown me the problem, wood falling to the floor. “Can you fix that?” He sternly spoke aloud to me over the crowd as he shook his head in a No Way fashion, suggesting I was not the man for the job. My reply was classic and immediate. “Where’s your coffee pot?” At this point, they all knew I was about to settle in to execute on this impossible challenge. 26 hours and two days later (2 13-hour days), the job was done!

I knew how easily the re-scrapped table and saddle moved following my scraping and returning lubrication (Mobil: Vacuoline 1405 oil) back to the v-ways. With the saddle and table back in the positions of the dreaded forklift push, I called the guys back over to the Okamoto grinder. After the crowd half-circled around the front of the machine, the smokers once again lit up their cigarettes and looked on at me standing before the grinder. “Well guys, it’s all done! Everything is beautiful again!” I then turned to face the machine and gave the saddle a good shove to get it riding up onto the oil. After a couple back and forth movements with the saddle, my right hand left the saddle and began moving the table right to left. They all looked on as I was moving both the saddle and table single handedly back and forth effortlessly. I then let go of both saddle and table and they coasted to a stop. I turned to face my audience of working men. One guy was picking his cigarette up off the floor because his jaw hung open and his lip-held cigarette fell from his mouth. A clapping applause and verbal outbursts of absolute amazement filled the shop. The shop owner, who was in the crowd of men, smoothly approached me and began to quietly speak. His next sentences changed my life forever! What I’ll tell you here is that he was flabbergasted that I returned those machinery ways back to mint condition!

Waymint began its formation as I was driving away from this job site, per the owner’s strong advice. Making the ways mint again and deciding to name my future business “Waymint” happened mere hours after completing the job.

That was the last scraping job I would execute on where I handed the check to another individual not responsible for the scraping effort. The next payment would be mine and it became my mission to make this a reality, God willing!

Early 2010 was also the year communications were sent out to the industrial community informing them of who we were and what we do. Two months after this effort our first phone call arrived and would be our first Waymint customer. Oddly, our first job was not a scraping service but was an Okamoto column-type spindle rebuild, which we accepted and successfully completed! Our business heartbeat had begun beating. We were alive with our first dollars and officially on the path that took a lifetime to find and ride upon.

In 2025, Waymint enters its 15th year of independent success. Our on-site travels in scraping Okamoto surface grinders have taken us to both the east and west coastlines, to the Canadian and southern borders and approximately 40 non-border US states. Customers love what we do and the people at these customer locations love seeing the service happen right before their very eyes. The installation and return of OEM accuracy back into Okamoto grinders happens over the course of approximately ten business days. The disassembly of the grinder and clean-up of all removed parts is part of the process. Worn turcite too far eroded to rescrape gets replaced on-site and scraped-in following the curing of the epoxy adhesive and the trimming down of the oversized turcite strips. Rulon is a desired replacement for old turcite in many cases. Either way it all gets done, accuracies are better than new machine accuracies, the machine is reassembled, new oil flows through the machine’s system, oil filter is cleaned, hydraulic oil pressure is optimized and the table top, chuck bottom and topside are ground in with freakish precision suitable for NASA, Tesla and aerospace rocket parts. Seeing is believing!

Hire Waymint, Inc., for your Okamoto OEM accuracy rebeautification and you will most definitely “see” and in the end, upon our completion, you will most certainly “believe.” Our service to accurately restore Okamoto grinders on-site is the honor of our lives and we look forward to hearing from you. Give us a call to discuss your Okamoto surface grinder(s). We humbly thank you for your read today and your future considerations for on-site OEM Okamoto scraping services.

Cordially,

Daniel W. Raciak

President / Founder

Waymint, Inc.