On-Site OEM Hand-Scraping for Okamoto Surface Grinders.

SERVICES

Way scraping, gib scraping (within column) & spindle rebuilding.

- LINEAR

- SADDLE TYPE

- COLUMN TYPE

- ROTARY

- OD

Waymint, Inc., are ex-Okamoto assembly and master hand-scraping technicians. We auto-travel anywhere in the continental United States to hand-scrape Okamoto surface grinders on-site back to brand new OEM accuracy. We actually surpass a two tenth .0002” Okamoto standard by double (.0001”) and provide the Okamoto customer with flatness grinding capabilities never before experienced. Individual part grinding accuracy flatness in the millionths.

When an Okamoto grinding operator can no longer meet or exceed needed tolerance on a part grind, commonly .0002” or better, the operator then reaches into his bag of tricks by re-grinding, re-dressing, part rotation, part flipping, relocating part to a different mag-chuck area, wheel change, grinding speed alteration, decreased downfeed amounts and coolant improvements. When all these applications still result in failure to achieve a needed grind tolerance, the operator discusses a plan of attack with his superior and a chuck topside regrind is usually the next move. When this fails… our phone rings or an email finds our In-Box. Time for Waymint, Inc., to visit and rescrape the ways to restore your machine’s accuracy. Works every time!

Need hand-scraping on a non-Okamoto machine? Give us a call or send us an email to discuss your service needs. If it needs to be precision-scraped, we can scrape it!

Solid flooring required

For Waymint to be successful, we require the machine to be seated on solid flooring without cracks or hollow voids beneath the flooring. Our machinist bubble level can’t be meddled with by buckling floor segments when level checking the moving components of the surface grinder. Generally, if your machine is positioned on solid industrial grade concrete without cracks, you’re good to go!

Space requirements

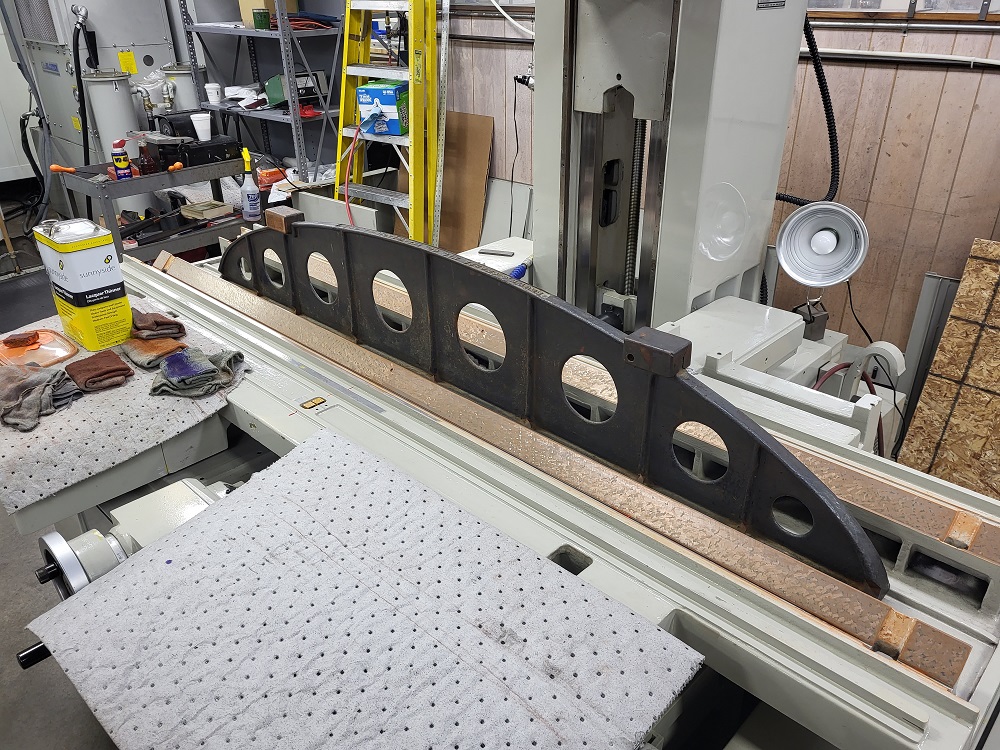

Secondly, we require space around the front of the machine for the safe removal of the chuck, table and saddle. An overhead shop crane or a forklift works fine. Some customers provide their best forklift driver to assist in the lifting challenges, which is fine. We guide them along by stating what’s needed and the operator simply follows safe and sound directions from Waymint, Inc. Everything goes very smoothly.

Work area requirements

Thirdly, Waymint requires a pair of heavy duty work horses or a heavy duty steel table that is capable of safely supporting the saddle and the table, independently, not paired together. So, once we confirm good flooring, space around the front of machine, overhead crane and/or forklift availability and a pair of work horses and-or a heavy duty table, victory is then assured.

How we do it

We partially disassemble your grinder; wheel guard, splashguards, coolant tank removal, chuck removal, table removal and saddle removal. From here we assess the turcite condition. We can use, or needs replacement. Not a problem. Scrape the saddle back to OEM accuracy, scrape the table back to OEM accuracy, change the oil, clean the filter, purge the oil lines, reassemble the grinder and grind in the table top surface. Following a bottom and chuck topside grind-in, you’re ready to rock and roll!

Why Use

?

CUSTOMER BENEFITS

No machine pack-up

No machine rigging

No machine shipping

No 3-4 month long wait times like other rebuilders offer

No inexperienced non-Okamoto techs servicing your machine

Waymint is 75-Years experience with Okamoto reciprocating grinders

Waymint is OEM Okamoto master assembly and scraping technicians

Waymint completes scraping service on-site in 10 days or less

Customer benefits: return of grinding duties within 10-day window

-

Okamoto Scraping – Waymint, Inc., are the only OEM OKAMOTO master assembly, hand-scraping and spindle building technicians that execute on-site in America!

-

No machine pack-up

-

No machine rigging

-

No machine shipping

-

Okamoto Scraping – Waymint, Inc., offers full view transparency while conducting Services

-

Okamoto Scraping – Waymint, Inc., completes full service saddle-type scraping task in 2-weeks or less

-

No non-Okamoto Techs servicing your Okamoto Surface Grinder

-

Restored grinder generating revenue $$ / back to operational duties 10-days or less

-

Okamoto Scraping – Waymint, Inc., is 75-Years experience with Okamoto Surface Grinders

MISSION STATEMENT:

Okamotoscraping.com consists of two, ex-Okamoto Corporation OEM master Hand-Scraping, Spindle Rebuilding and Assembly technicians. Our goal is to provide on-site high-precision accuracy services into reciprocating Okamoto surface grinders for business manufacturers Nationwide! First in timeliness and precision!

CONCLUSION

Depending on the machine size, service order and level of machine deterioration, almost all machines are back up and running in 10 business days or less.

WAYMINT TERMS

Waymint requires Half-Down and a PO to begin services.

Waymint final balance due NET-30 following completion of service.

WAYMINT TRAVEL

Waymint DOES NOT Fly! One way auto-travel 10 hrs or less is $100.00 per hour.

Anything in excess of a 10 hour one way travel is a Rental Car situation. Approximately 1k to 1.25k per week.

Waymint makes deals on long distance travels across the United States. Any travel in excess of three states is deal-making territory for the customer.

LODGING

Rural Lodging $250.00 per night. City Lodging $350.00 per night.

MEAL FEES

$120.00 per day. This is $60.00 a day for two master technicians.